Although it is not required or part of the New Jersey home inspector regulations in New Jersey New Jersey home inspectors should inspect for duct leaks in HVAC systems. The majority of homes in New Jersey are equipped with central forced air systems that rely on ductwork to deliver conditioned air from the furnace to the rooms of the home. If the ductwork is not sealed properly this can create poor performance and create hot or cold temperatures in the home caused by the loss of heated or cooled air. Ductwork air leakage issues can be more problematic at the furnace or the air handler cabinet where air pressures are the greatest. Seems or holes in the cabinets should be properly sealed to prevent air leakage from these openings. The only areas where conditioned air should be able to escape the HVAC duct system in the furnace is when it exits at the supply registers. The only area where air should be able to enter the return duct system is that the return grills.

In an energy efficient home all HVAC equipment including the furnace and air handler and the ductwork should be located inside the home when the equipment is located inside the home sometimes it is believed that it does not have to be properly sealed because the air is leaking into the home’s interior. It is not being lost into an attic or a crawlspace or other area that is not conditioned. NJ home inspectors should evaluate the air sealing in the visible areas of duct work and on the air handler or furnace cabinet. Sealing cabinet air leaks is still very important for improving efficiency of the HVAC system because it helps to enable maximum airflow to the ductwork. In a forced air system, the highest air pressures are experienced at the air handler or furnace with pressures increasing the closer one gets to the fan. Because of this fact it is very important to seal all of these openings especially around the furnace or air handler where air can escape.

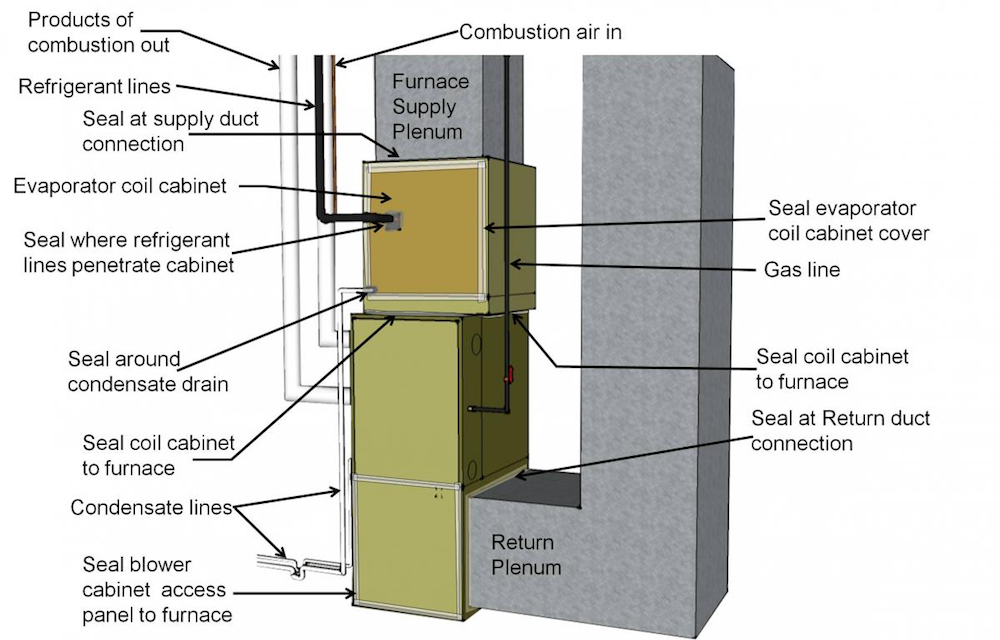

Furnaces are generally equipped with a refrigerant coil called an evaporator coil this is located typically at the top of the furnace unit. The purpose of the coil is to provide cooling during the summer months. The connection point between the evaporator coil cabinet in the furnace cabinet is likely to be the point of highest air pressure. This point can create significant air leakage. Coil cabinets do not always fit tightly on top of the furnace. Many evaporator coil cabinets have a slightly larger footprint then the furnace creating seems where the two boxes meet which can allow air leakage. The coil cabinet should be sealed properly to the furnace using mastic or unapproved HVAC foil tape.

Air handlers, furnaces and coil units ship from the factory with knockouts, penetrations or holes for installing piping and wiring. Any not used openings should be sealed along with any gaps around the wiring and piping that penetrates the unit. This is another significant problem where air can leak from. Openings where the condensation line and the refrigerant lines penetrate the evaporator coil unit will also have high pressure. Seal around these lines with appropriate putty. The putty is purchased in strips or cords. This type of putty will remain flexible and malleable so it can be removed and reapplied.

The third point of high pressure is the area of the cabinet that contains the blower fan. This is generally considered one of the most concerning areas for air leakage especially if the furnace is in a garage or any other area where chemicals are stored or where their exposure to carbon monoxide. Any seems gaps are opening should be properly sealed with mastic and fiberglass tape.

The furnace or air handler and all ductwork should be installed within the confines of the home. An air handler or furnace should be selected that has a manufacturer’s designation showing that air leakage is no more than 2% of the design airflow rate when tested. United laboratory approves gaskets, mastic and fiberglass mesh should be each used to seal all cabinet seems and openings between the air handler or furnace cabinet and the evaporator coil unit. The supply plenum and the return plenum should also be properly sealed to avoid air leakage. All unused knockouts should be sealed with a United laboratories listed tape or mastic. All fixed seems in the cabinetry and all seams between the cabinets and the supply and the return plenums should be sealed with mastic or fiberglass mesh fabric. A putty should be used to seal the inside of the high voltage wire conduit in order to avoid air leakage at the air handler after the wiring has been installed.

There is a code reference for this required air sealing:

IR CM 1601 “The ductwork joints, seams and connections must be securely fastened and sealed using gaskets, mastic, mastic fabric systems, liquid sealants or tapes.”

Leaking ducts can discharge conditioned air into attics and crawl spaces or pull air in from the same types of spaces. Both outcomes are energy wasters and lower the volume of conditioned air both heated and cooled that reaches the home. These openings can also cause problems with circulating contaminants and odors. New Jersey home inspectors can check that HVAC systems are properly sealed at all seams and connections with approved tape or mastic. New Jersey home inspectors should educate their clients about improving energy efficiency and safety by taking the simple step at properly sealing these openings in the furnace and ductwork.