New Jersey home inspectors should be familiar with Pex water supply pipes. Home inspectors will come across Pex water supply pipes while performing home inspections. Pex piping is often found in newer homes and recently renovated homes. Home inspectors in NJ should understand the basic differences between the two most common supply pipe materials.

Pex (cross-linked polyethylene) water supply pipes are a type of flexible plastic piping that is commonly used for water supply lines in residential and commercial construction. Pex piping is made by cross-linking the molecules of the polyethylene material, which increases the strength and durability of the pipe. Pex pipes are flexible and can be bent and shaped to fit around corners and obstacles, which makes them easier to install in tight spaces. They are also resistant to corrosion and can withstand high temperatures, making them a good choice for hot water lines. Pex pipes are typically white or blue in color and are available in a range of sizes to suit different water flow needs.

Pex piping is a flexible plastic piping that is commonly used for water supply lines in residential and commercial construction. Copper water supply pipes are also a popular choice for water supply lines due to their durability and resistance to corrosion. However, both types of pipes have their own set of advantages and disadvantages, and the choice between the two ultimately depends on the specific needs of the project.

One of the main advantages of pex piping is its flexibility. Pex pipes can be bent and shaped to fit around corners and obstacles, which makes them easier to install in tight spaces. They are also less prone to bursting or leaking due to freezing, as the flexibility of the pipe allows it to expand and contract with changes in temperature. Pex piping is also resistant to corrosion, which makes it a good choice for areas with hard water.

On the other hand, copper water supply pipes are known for their durability and long lifespan. Copper pipes can last for over 50 years, making them a long-term investment. Copper pipes are also resistant to corrosion, which makes them a good choice for areas with acidic water. Copper pipes are also easy to repair, as they can be joined using solder.

One potential problem with Pex piping is that it can be damaged by UV light and may need to be protected if it is installed in an outdoor setting. Copper pipes, on the other hand, can be damaged by acidic water, which can corrode the pipes over time.

In terms of cost, Pex piping is generally less expensive than copper piping. Pex pipes can cost up to 50% less than copper pipes, depending on the size and type of pipe needed. However, the cost of installation may be higher for Pex piping, as it requires specialized tools and fittings. Copper pipes, on the other hand, can be more expensive upfront, but may have a lower cost of installation due to the fact that they can be joined using traditional soldering techniques.

Overall, both Pex and copper water supply pipes have their own set of advantages and disadvantages. Pex piping is generally less expensive and easier to install but may not be as durable as copper pipes. Copper pipes are more expensive upfront but have a longer lifespan and are easier to repair. The choice between the two ultimately depends on the specific needs of the project, including budget, installation requirements, and the local water conditions.

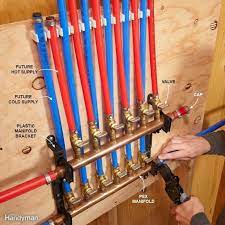

Pex piping is typically joined using mechanical fittings, which are inserted into the end of the pipe and secured in place using a clamp or a crimp ring. The fittings are designed to create a secure, watertight seal, and can be easily removed or disassembled if necessary. There are several types of fittings available for Pex piping, including crimp fittings, clamp fittings, and push-fit fittings.

Crimp fittings are the most common type of fittings used for Pex piping. They consist of a fitting with a small groove, and a crimp ring that is placed over the fitting and the pipe. The crimp ring is then squeezed using a specialized tool, which compresses the ring around the fitting and the pipe, creating a secure seal.

Clamp fittings are similar to crimp fittings, but they use a clamping mechanism to secure the fitting in place rather than a crimp ring. The clamp is tightened around the fitting and the pipe using a special tool, creating a watertight seal.

Push-fit fittings are another type of fitting that is commonly used for Pex piping. These fittings do not require any special tools or clamping mechanisms and can be simply pushed onto the end of the pipe and secured in place using a collet. Push-fit fittings are easy to use and can be removed or disassembled if necessary.

New Jersey home inspectors should be able to identify the most common problems found in Pex piping installation.

- Kinking: PEX pipes are flexible, but they can become damaged if they are bent too sharply. This can cause the pipe to kink, which can reduce water flow and potentially cause leaks.

- Expansion and contraction: PEX pipes expand and contract when the temperature changes, which can cause them to pull away from fittings or break if they are not properly secured.

- Oxidation: PEX pipes are resistant to corrosion, but they can still be affected by oxygen in the air, which can cause them to become brittle over time.

- Compatibility with certain materials: PEX pipes are not compatible with certain materials, such as solvents and fuels, and should not be used in systems where these substances may be present.

- Difficulty of repair: PEX pipes are difficult to repair if they become damaged, as the damaged section must be cut out and a new fitting installed. This can be time-consuming and costly.

There are several ways to join copper water supply pipes, including soldering, brazing, and using compression fittings.

Soldering is a common method of joining copper pipes, where a heated soldering iron is used to melt a small amount of soldering wire, which is then used to join the pipes together. To do this, the pipes are first cleaned with a wire brush and coated with a flux compound to help the soldering wire bond to the pipes. The soldering iron is then used to heat the area where the pipes will be joined, and the soldering wire is applied to the joint until it melts and forms a seal.

Brazing is similar to soldering, but it uses a higher temperature and a different type of filler metal (brazing alloy) to join the pipes. Brazing is generally stronger than soldering and is often used for larger diameter pipes or for pipes that will be subjected to higher pressures.

Compression fittings are another option for joining copper pipes. These fittings consist of a nut and a sleeve that are tightened around the pipes to create a seal. Compression fittings are easy to use and do not require the use of heat, but they are generally not as strong as soldered or brazed joints and are not recommended for use in high-pressure systems.

Home inspectors in New Jersey should be able to identify some of the installation issues found in copper water supply pipes. There are several common problems that can arise during the installation of copper water supply pipes:

- Leaks: Copper pipes can develop leaks due to various factors, such as corrosion, damage, or improper installation.

- Poor soldering: If the soldering process is not done correctly, the joints between the pipes may not be properly sealed, leading to leaks.

- Corrosion: Copper pipes are prone to corrosion, especially in areas with high acidity or high levels of chlorine. This can cause the pipes to weaken and potentially fail.

- Kinking: Copper pipes are rigid and can be damaged if they are bent too sharply. This can cause the pipe to kink, reducing water flow and potentially causing leaks.

- Poor pipe preparation: If the pipes are not properly cleaned and fluxed before soldering, the joints may not bond properly and may leak.

- Insufficient support: Copper pipes must be properly supported to prevent sagging or bending, which can cause the pipes to fail or become damaged.

Home inspectors in New Jersey will have to evaluate both copper water supply pipes and Pex water supply pipes. Home inspectors should be able to explain to their clients the differences in both types of piping and to be able to identify potential defects in both types of piping.